Kubbada Kubadda Ku Fadhiista ee Bir adag ee Adag oo ku rakiban ISO5211 Flange Sare

Biraha Kubadda Ku Fadhiya

Kubadda kursiga birta waxaa loo doortaa dhexdhexaadiyaha culus ee culus sida walxaha adag, xoqan, heerkulka sare ama heerka cadaadiska sare ama qof kasta oo ka mid ah xaaladda la sheegay oo la isku daray, dhuumaha caadiga ah sida kiimikooyinka dhuxusha, saxarka & warqadda iyo warshadda saliidda cayriin iwm. Waalka kubbadda fadhigu wuxuu muujinayaa waxqabadka xidhidhiyaha wanaagsan, adeeg waqti dheer ah, xoog yar iyo marka la barbardhigo cadaadiska ka yar adeega kor ku xusan.Waalka guud sida globe iyo gate valve ma buuxin karo xaaladan shaqada, sidaas awgeed galka kubbadda kursiga birta ayaa koraya baahiyo badan oo adeeg oo daran.

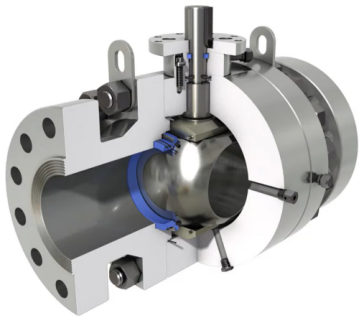

● Kubbada Trunnion waxay leedahay jirrid sare iyo hagaha trunnion hoose waxay yareeyaan qulqulka stem

● Garaafyada daboolida inta u dhaxaysa fadhiga iyo jirida oo ku habboon heerkulka sare

● Piston Inconel X750 kursiga guga wuxuu dheellitirayaa cadaadiska kursiga

● Dhiig-bax labalaab ah iyo nidaamka xannibaadda

● Dabka badbaadsan iyo jirida ka hortagga afuufinta

● Waalka kubbadda kursiga birta ee ku rakiban trunnion wuxuu caadi ahaan leeyahay qaab dhismeedka daboolida kursiga ee meesha kubadda laga soo galo.Labada kursi waxay si madaxbanaan u gooyeen dhexda meesha laga soo galo iyo meesha laga soo galoba si loo gaadho shaqo labanlaab ah.Marka waalka kubbadda la xiro, xitaa haddii labada daraf ee meesha laga soo galo iyo meesha laga soo galo waalka la cadaadiyo isku mar, daloolka dhexe ee waalka iyo marinnada labada daraf waa la xannibi karaa midba midka kale, dhexdhexaadinta soo hartayna gudaha godka dhexe waxaa lagu sii dayn karaa iyada oo loo marayo valves gargaarka.

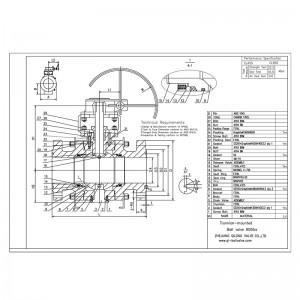

FIGTrunion oo ku rakiban nooca waalka kubbadda

Fadhiga birta ah ee kursiga waalka kubbadda furan oo fadhi ku dhow jaantuska qaybta.

Kursi furan

Kursiga waa la xidhay

ARAN Metal Kubada Kubada Ku Fadhiisa Inta badan waxaa loo isticmaalaa xaaladaha adeega daran sida dareeraha daxalka sare iyo nabaadguurka oo leh qaybo adag iyo heerkul sare ama cadaadis sare, xaaladahan oo kale waalka kubbadda fadhiya ee jilicsan ma noqon karo mid waara sababtoo ah farqiga alaabta kursiga.Marka la codsado, macluumaadka dhexdhexaadinta valve iyo heerkulka ayaa aad muhiim ugu ah injineerka iibka ARAN si uu u doorto nooca saxda ah.

| Range Production | Kubadda Kubadda Kursiga ee Birta |

| Nooca walxaha | Bir been abuur ah ama birta tuurka ah: birta kaarboon, LTCS, birta daawaha, birta aan lahayn, birta duplex, bronze, Inconel, Hastelloy, Monel, Incoloy iwm. |

| Koodhka alaabta | WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L |

| Nooca fadhiga | Qalabka dahaarka adag ee fadhiya birta sida CRC/TCC/STL6/Ni60/STL |

| Cabbirka | NPS 2"~24" (50mm ~ 600mm) |

| Cadaadis | ASME Class150~2500LBS (PN16~PN420) |

| Hawlgalka | Buug-gacmeedka, Sanduuqa Gear-ka Gooryaanka, Dhaqdhaqaaqa Pneumatic, Dhaqdhaqaaqa Korontada, Qalabka Haydarooliga-korontada |

| Dhexdhexaadinta shaqaynaysa | WOG |

| Heerkulka shaqada | ugu badnaan 540 ℃ |

| Heerarka Wax-soo-saarka | API/ANSI/ASME/EN/DIN/BS/GOST |

| Naqshad& MFG code | API 608/API 6D/ISO17292/ ISO 14313/ASME B16.34/BS5351 |

| Waji ka waji | ASME B16.10,EN558 |

| Dhamaystirka Xidhiidhka | Flange RF/RTJ ASME B16.5/EN1092-1/GOST 33259 ;BALKII WELD BW ASME B16.25 |

| Tijaabada & Kormeerka | API 598, API 6D,ISO5208/ISO 5208/EN12266/GOST 9544 |

| Naqshadaynta aasaasiga ah | |

| BADBAADADA DABKA | API 607 |

| KA-hortagga STATICS | API 608 |

| Astaamaha jirida | Kahortagga qarxinta caddaynta |

| Nooca kubbadda | Gelida dhinaca |

| Nooca kubbadda sabaynaysa | hal dhinac shaabadeynta ama shaabadeynta labada dhinac |

| Nooca kubbadda Trunion | Laba-dhiigbaxa iyo xannibaadda |

| Bore nooca | Dhaleec buuxa ama Boor la dhimay |

| Dhismaha Bonnet | Dabool daboolan ama koofiyad alxan oo buuxda |

| Habayn ikhtiyaari ah | NACE MR0175, MR0103, ISO 15156 u hoggaansanaanta |

| ISO 5211 DHULKA PAD usheeda dhexe ee qaawan | |

| Xaddid Bedelka | |

| Qalabka quful | |

| Ku habboonaanta adeegga ESDV | |

| Shaabadeynta labada jiho ee daadinta eber | |

| Kordhi stem adeega cryogenic | |

| Tijaabada aan burburin (NDT) ilaa API 6D, ASME B16.34 | |

| Dukumentiyada | Dukumentiyada keenista |

| EN 10204 3.1 MTR Warbixinta tijaabada walxaha | |

| Warbixinta kormeerka cadaadiska | |

| Warbixinta xakamaynta muuqaalka iyo cabbirka | |

| Dammaanadda alaabta | |

| Buugga hawlgalka Valve | |

| Alaabta asalka ah |

Dhuumaha Saliida iyo Gaaska

Daboolka birta ku fadhiya ee loogu talagalay in lagu daboolo baahiyaha adeegga muhiimka ah ee warshadaha saliidda iyo gaaska.Warshadahani waxay u baahan yihiin shaabado adag oo la isku halayn karo oo aan eber fursad u lahayn daadinta.soosaarka QL th

Koronto dhalin

Qulqullada birta ku fadhiya ee QL waxay bixiyaan xalal la isku halayn karo, dhaqaale iyo waqti dheer oo loogu talagalay codsiyada muhiimka ah ee dhirta korontada.Iyada oo adkaysiga dahaarka kursiga adag iyo dayactirka yar ee QL biraha kubbadda barafka ayaa ah furayaasha ku habboon codsiyada warshadaha tamarta.

Kiimikada batroolka

Xaaladaha hawleed ee halista ah, hawlgallada badbaadada muhiimka ah, iyo asiidhyada wasakhaysan ee ku jira dhirta wax-soo-saarka batroolka waxay u baahan yihiin biraha la geliyo.Waxqabadka sare iyo qallafsanaanta dusha sare ee birta QL ee fadhiisanaysa galka kubbadda heerkulka sare waxay hubin doontaa daacadnimada iyo badbaadada hawlgalka oo dhan.

Warshadaha macdanta

Jawiga qallafsan ee warshadaynta macdan qodista waxa ay u keeni kartaa dhaawac halis ah valvyada.Qalabka birta ku fadhiya ee QL waa kuwo adkeysi u leh abrasion iyo kursiga daahan gaarka ah waara.Waxay ku fiican yihiin codsiyada sida xadhkaha qiiqa, go'doominta bamka dareeraha ah iyo duritaanka aashitada.

Warshada saxarada iyo waraaqaha

Warshadaha saxarka iyo waraaqaha waxay u baahan yihiin go'doon eber ah iyo walxaha khatarta ah.Ma aha oo kaliya in alwaaxyada fadhiya birta ay bixiyaan go'doon la isku halleyn karo, waxay sidoo kale ka kooban yihiin daahan adag oo gaar ah.Tani waxay kor u qaadaysaa xidhitaankooda, daxalka iyo caabbinta nabaad-guurka, si ay u kordhiyaan noloshooda adeeg.